Step inside our process, where we transform nature’s fibers into premium jute products. Through advanced manufacturing, strict quality control, and decades of expertise, GFTCL delivers export-grade jute solutions trusted worldwide.

See how we blend tradition with technology to create products that stand the test of time. Advanced processes and skilled expertise ensure consistent quality, faster production, and reliable export performance.

Take a behind-the-scenes look at the care and attention that goes into every detail. Jute manufacturing facility combines skilled craftsmanship, strict quality control, and efficient workflows to deliver export-grade jute products with consistency and precision.

Feel the precision in every fiber, ensuring our products meet the highest standards. Best looms, controlled weaving density, and rigorous inspections ensure uniform strength, durability, and export-grade performance in every jute product.

Experience the exceptional craftsmanship and artistry that make our jute products truly special.Skilled artisanship combined with modern quality controls delivers refined finishes, consistent performance, and export-grade reliability across every jute product.

We’d love to bring your ideas to life with our eco-friendly jute solutions. Have questions or ready to collaborate? Fill out the form below, and we’ll get back to you as soon as possible.

For Raw & Processed Jute Inquiries:

For Sacking, Hessian & Yarn Inquiries:

Address

At GFTCL, our expert leadership drives us toward innovation and growth in the jute industry. With ISO 9001:2015 and ISO 14001:2015 certifications, we uphold the highest standards of quality and environmental responsibility.

Promoting Sustainable Jute

We aim to lead the global transition toward eco-friendly jute solutions through responsible sourcing and advanced processing. By promoting sustainably sourced raw materials such as kenaf fiber, we support greener alternatives across textiles, construction, and automotive applications. Our focus on sustainability ensures long-term environmental value without compromising performance or quality.

Global Jute Innovation

We strive to introduce innovative jute products to global markets by leveraging Bangladesh’s competitive advantage in sustainable natural fibers. Through continuous research, product development, and process improvement, we create high-performance jute solutions for evolving industry needs. This innovation-driven approach opens new opportunities for growth across agriculture, industry, and eco-conscious markets worldwide.

Since 1988, GFTCL has been a reliable Bangladesh jute exporter and raw jute supplier, serving international B2B buyers with a full range of eco-friendly jute products. Our core products include raw jute fiber, jute yarn, hessian cloth, jute sacking bags, jute twine, and kenaf fiber, supplied to importers, wholesalers, and industrial users across North America, Europe, and Asia. As an ISO 9001 and ISO 14001 certified jute manufacturer, we follow structured quality management systems and sustainable production practices to meet global export requirements.

Our jute processing and manufacturing facility in Sarishabari, Bangladesh handles the complete production workflow, including raw jute sorting, fiber carding, spinning, cutting, pressing, and balling. This allows us to maintain consistent quality for bulk jute fiber and jute yarn exports. With decades of experience in jute product manufacturing and international trade, GFTCL is recognized as a dependable jute yarn supplier, hessian cloth exporter, and jute packaging supplier for agricultural, industrial, and commercial applications worldwide.

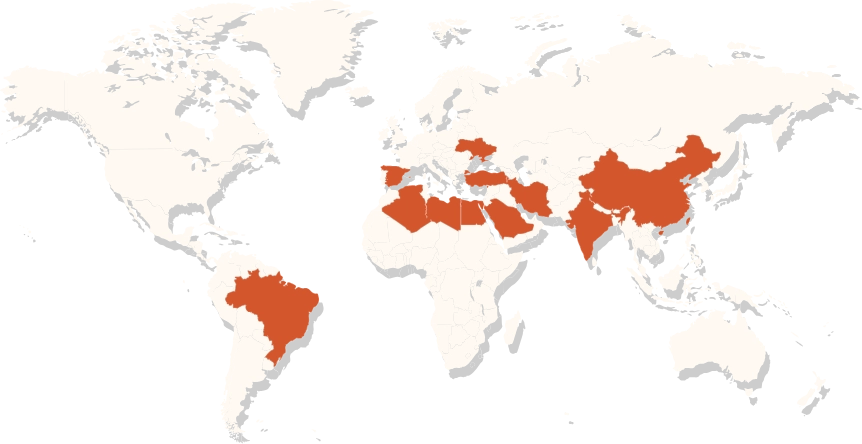

Partnering Globally for Sustainable Jute Products

Over the last thirty years, we are exporting Jute/Kenaf fibers to the traditional Jute and textile mills,

constructions industries, automotive sector, paper-pulp industries and non-woven industries worldwide.

Where Quality and Precision Come Together

Our warehouse is where the journey of every jute fiber begins.

We carefully store raw jute and finished products in controlled, well-managed facilities to preserve fiber quality and performance. Proper handling, ventilation, and organized storage ensure materials remain protected from moisture and damage. This systematic warehousing approach keeps every batch ready for the next stage of production and timely export.

Our carding facility, the raw jute fibers undergo a meticulous process of untangling and refining.

Using state-of-the-art machinery, we carefully clean, align, and refine jute fibers to achieve uniformity and consistency. This process removes impurities while improving fiber strength and smoothness. Precise carding ensures a high-quality base for producing durable yarns and premium jute fabrics.

Jute fibers naturally have a rough texture, so we’ve dedicated a facility to softening them.

By carefully treating each batch, we enhance fiber flexibility, softness, and workability. At GFTCL, this controlled treatment prepares jute to perform optimally during weaving and fabrication. The result is eco-friendly jute products that combine comfort, durability, and consistent quality for global markets.

In the cutting facility, we ensure that each jute fiber is perfectly measured for its intended use.

Whether for yarn, fabric, or industrial applications, we cut jute fibers to precise, standardized lengths. This accuracy ensures uniformity, performance consistency, and smooth processing at every stage. By maintaining strict dimensional control, GFTCL guarantees reliable quality for the next phase of production.

Once the fibers are prepared, they are carefully balled into compact bundles.

This process simplifies handling, storage, and transportation while preserving the natural quality of the fibers. At GFTCL, we carefully execute the balling process to ensure every bundle is uniform, compact, and secure. Each finished bundle is fully prepared for smooth processing, storage, or global shipment.

Spinning is where the magic happens, as the carded and softened fibers are twisted into strong, durable jute yarn.

Our spinning facility combines advanced technology with skilled craftsmanship to produce yarn that is consistent, strong, and dependable. Each thread is carefully monitored to ensure uniform quality and performance. This precision makes our yarn the reliable foundation for upholstery, packaging, and eco-friendly jute products.

The weaving facility is where our yarns come to life, turning into the beautiful fabrics that our customers cherish.

With a strong focus on precision and quality, our advanced looms expertly interlace jute yarns into durable, eco-friendly fabrics. Each weave is carefully controlled to ensure strength, consistency, and performance. From hessian cloth to premium jute bags and specialized textiles, our fabrics are built to meet global standards.

Our packaging team steps in to ensure they are carefully wrapped, labeled, and ready for delivery.

At GFTCL, we carefully prepare every finished product, jute sacks, yarn, and fabrics for safe and secure shipment. Proper packing and handling ensure each item is protected during transit and arrives in perfect condition. This final step reflects our commitment to quality from production to delivery.

Fibre at Our Core, Promoting Indigenous Raw Materials and Constantly Exploring New Avenues for Sustainable Innovation. At GFTCL, we actively work with Jute which is natural fibre. It is also called kenaf, burlap, Hemp, Flax, Ramie, Roselle Fiber. It is used to develop sustainable eco-friendly fiber-based solutions that reduce environmental impact and support green industrial growth.

For over 35 years, We at GFTCL have been trusted to deliver top-quality jute products, fostering lasting relationships and ensuring excellence in every stage of production and export. Our experience, consistency, and commitment to quality make us a reliable global partner in sustainable jute solutions.

At GFTCL, we believe in doing our part for the planet. Our 100% biodegradable and recyclable jute products reflect our dedication to sustainability, leading the green revolution one product at a time. By combining responsible sourcing with efficient production, we help global buyers reduce environmental impact without compromising quality or performance.

Serving markets worldwide, GFTCL provides sustainable, high-quality jute products while building strong, long-term relationships and ensuring customer satisfaction across the globe. Through reliable supply, consistent quality, and responsive support, we help our partners succeed in diverse international markets.

Serving markets worldwide, GFTCL provides sustainable, high-quality jute products while building strong, long-term relationships and ensuring customer satisfaction across the globe.

Through reliable supply, consistent quality, and responsive support, we help our partners succeed in diverse international markets.

Jute, known as the Golden Fibre, is a strong, eco-friendly natural fiber grown primarily in Bangladesh. It’s prized for its durability, biodegradability, and versatility. Used in packaging, textiles, and agriculture, jute is the “Fibre of the Future”, with varieties like White Jute and Tossa Jute being commercially significant. Jute has long been at the center of sustainable material innovation, offering a natural alternative to synthetic fibers. As a plant-based fiber, jute stands out for its strength, breathability, and environmental benefits. High-quality Jute Fiber is processed into a wide range of products including Gunny sacks, Burlap Bags, Burlap Sack Bags, and heavy-duty Sacking solutions used globally for agricultural and industrial packaging.

Bangladesh remains the world’s leading source of Raw Jute, supported by fertile river basins and generations of farming expertise. From raw form, jute is transformed into Semi Process Jute, then further developed into Hessian Cloth, Sacking Cloth, Yarn, and Jute Rope. These materials serve diverse industries from food and coffee export to construction and retail packaging. Products like coffee bags, cheap burlap bags, and jute burlap rolls are widely used due to their durability and cost efficiency.Jute is often compared with kenaf, another sustainable natural fiber. Today, many manufacturers work with both jute and kenaf to create innovative products such as Kenaf bags, cloth, and yarn. Manufacturer & Exporter solutions that meet modern sustainability standards. This combination expands applications across packaging, textiles, and industrial uses while reducing environmental impact.

As a Trusted Jute Bag, Cloth, Yarn Exporter and Manufacturer, Bangladesh supplies global markets with consistent quality and scalable production. Buyers searching for jute bags near me, Jute Kenaf bags wholesale, or export-grade burlap and Material Hessian rely on Bangladesh for reliable supply and competitive pricing. From traditional Gunny sacks to refined hessian and sacking fabrics, jute continues to replace plastic and synthetic materials worldwide.With rising demand for biodegradable packaging, jute’s role is stronger than ever. Its renewable nature, versatility, and proven performance make it a preferred material for businesses seeking sustainable growth. As industries evolve, jute—along with complementary fibers like kenaf remains a cornerstone of eco-friendly manufacturing and global trade.